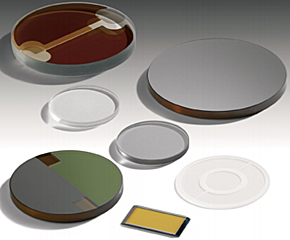

Optical coating or thin film coating refers to the manufacturing process of coating metal on glass, mirror, computer screen and optical fiber components. Optical coatings enable products to reflect light in different ways. Unlike uncoated products, coatings are usually done by machines operated by technicians who are responsible for programming or supervising machine processes. Some machines perform automated processes that do not require careful supervision.

Precision optical coatings are used in the manufacture of space telescopes. There are different types of requirements for optical coatings. In some cases, such as in mirrors, the desired effect is to produce a product with a high degree of reflection. By selecting materials with opposite refraction levels and stacking them, you can increase the reflection in the finished product. For inexpensive mirrors, a typical optical coating material will coat the glass with aluminum. More expensive coatings, such as silver, produce more expensive mirrors because they reflect more light and therefore have higher quality.

The windows of the space shuttle use optical coatings. For the lens used in microscope or camera, optical coating is used to refract light, which is called dielectric coating. It is not only suitable for consumers, but also suitable for scientific equipment such as telescopes and lasers. Metallic layers such as magnesium and fluoride are deposited on objects that require coating (called substrates). The level of reflection or refraction can be titrated according to the number and thickness of the layers, the type of material, and the coating process used. One of the companies that benefit most from optical coatings is optical coating labs, California In the 1970s, the company became a major employer in the then relatively small town of Santa Rosa, where they designed non reflective computer screens, shuttle windows and mirrors. For Chandra X-ray telescope, the company's growing technological and innovative capabilities attracted the larger company JDS uniphase, which subsequently acquired the company in the late 1990s. Although the move seems to herald greater capacity for the company to increase production, in fact, it eventually dismantled almost all of its optical coating business. The decline in productivity over the past few years has resulted in the unemployment of about 1000 people. The collapse of the company coincided with the collapse of the telecommunications industry, because during this period, jDS Most of uniphase's work is focused on optical fiber components. Later, most of the work of optical coating has been transferred to overseas. Some small-scale businesses in the United States are specialized in coating specific products, but the failure rate of start-ups is very high. Many old machines are now sold to India or China and other foreign countries. It is believed that only new overseas companies are facing problems Only by employing an American consultant to repair the machine will the production of the optical coating be effective, because the technology is mainly used in the United States and patented.